Sustainable Development

Mabuhay Vinyl is committed to the preservation of resources and the protection of the environment as an essential part of its manufacturing and business practices. As such we have a documented Environmental Management System (EMS) that is communicated, implemented and accessible to all stakeholders. We have likewise initiated programs that will efficiently control and minimize waste, and prevent pollution in the production, storage and distribution of our products and raw materials.

MVC’s approach to sustainable development takes root from our corporate core values, in particular, social responsibility. We strive to continue being the country’s industry leader without jeopardizing development and growth for future generations. Our framework for sustainable development combines aspects of environmental protection, general health and safety, harmonious community relations and employee development in order to maintain sustainability in all our operations.

As part of achieving sustainability, MVC has committed itself to the United Nations Global Compact Initiative and continues to maintain open communication with its stakeholders to effectively put these commitments into practice. The company is also part of the voluntary Responsible Care program instigated by the global chemical industry that aims to improve health, safety and environmental performance on an international scale. Aside from these initiatives, MVC also conducts several small-scale projects aimed at addressing the three pillars of sustainable development, economic, social and environmental, and applying these on a community scale, in particular the communities surrounding MVC sites.

MVC ON GLOBAL WARMING

Since 2000, greenhouse gas emissions from MVC Iligan Plant was greatly reduced due to the conversion from the wasteful Diaphragm Cell Technology to the efficient Ion Exchange Membrane (IEM) technology. Most of the CO2 emissions of the plant come from the production of steam that is used to concentrate caustic soda from 11% to 50%. With the IEM technology, the caustic soda concentration coming out of the cell is at 32% thereby reducing the amount of energy needed to concentrate the product to 50%.

In 2013, MVC started to utilize the hydrogen gas co-product as supplemental feed for the plant’s boilers. This means lesser CO2 emissions as Hydrogen is a very clean fuel and only produces water upon combustion.

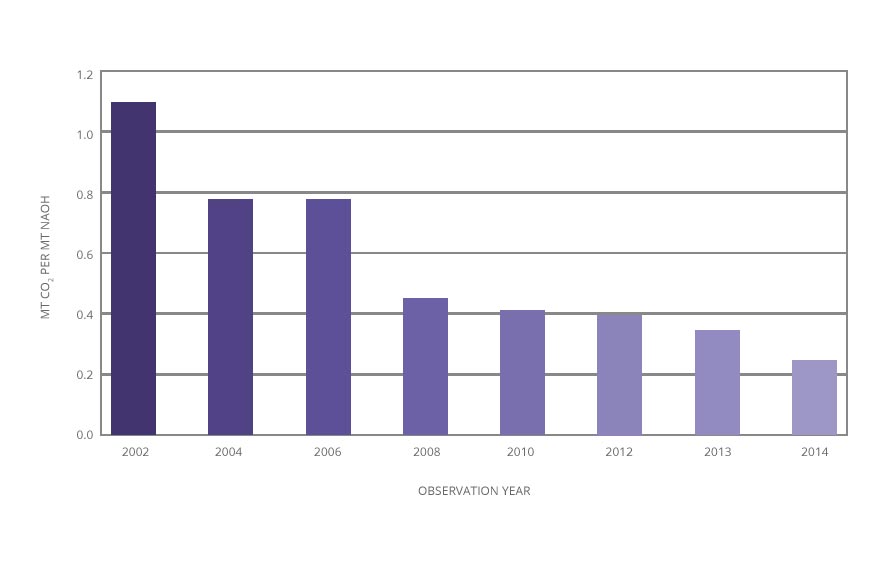

The figure below shows the decreasing trend of CO2 emissions from 2002 to 2014.

MVC’S YEARLY CARBON DIOXIDE EMISSIONS

MVC has reduced its emission of carbon dioxide through the use of the efficient Ion Exchange Membrane (IEM) technology for the production of caustic soda initially in 2003 with the IEM-1 Plant and again in 2008 with the IEM-2 Plant. Further reductions were achieved in 2013 – 2014 when the plant’s boiler was upgraded to enable the use of hydrogen gas as supplemental fuel and improvements in the steam distribution system